01 Apr

1.Definition of CNC Tools:

CNC tools refer to various tools used in conjunction with CNC machine tools (CNC lathes, CNC milling machines, CNC drilling machines, CNC boring and milling machines, machining centers, automatic lines, and flexible manufacturing systems).

2.Characteristics of CNC Machine Tool Tools:

- Excellent stable cutting performance: The tools have good rigidity and high precision, allowing for high-speed and heavy-duty cutting.

- Long tool life: Many tools are made of hard alloy materials or high-performance materials (such as ceramic blades, cubic boron nitride blades, diamond composite blades, and coated blades). High-speed steel tools mostly use high-performance high-speed steel containing cobalt, vanadium, aluminum, and powder metallurgy high-speed steel.

- Good interchangeability and fast tool change: Tools can be automatically and quickly replaced, reducing auxiliary time.

- High precision: Suitable for processing high-precision workpieces. Especially when using indexable inserts, due to the high repeat positioning accuracy of the tool body and insert, good machining quality can be achieved.

- Reliable chip breaking and chip removal performance: With CNC machining, stopping the machine arbitrarily to deal with chips is not feasible. Long chips generated during processing can affect operator safety and processing efficiency.

- Adjustable size function: Tools can be pre-adjusted (tooled) externally or compensated internally to reduce tool change adjustment time.

- Achieve serialization, standardization, and modularization: Serialization, standardization, and modularization of tools facilitate programming, tool management, and cost reduction.

- Multi-functional compound and specialization.

3.Main Application Areas of CNC Tools Include:

- Automobile Industry: The processing characteristics of the automobile industry are mainly large-scale, assembly-line production, and relatively fixed processing conditions. To optimize production, improve quality and efficiency, the automobile industry has very strict requirements on the efficiency and service life of tools. In addition, due to the use of assembly-line operations, mandatory uniform tool changes are usually adopted to avoid the entire production line being shut down due to tool changes, resulting in huge economic losses. This places unique high demands on the stability of tool quality.

- Aerospace Industry: The processing characteristics of the aerospace industry are high precision requirements and difficult-to-machine materials. Most of the components processed in this industry are made of tough and high-strength high-temperature alloys and nickel-titanium alloys (such as INCONEL718, etc.).

- Large Turbine, Steam Turbine, Generator, and Diesel Engine Manufacturing Enterprises: Most of the parts processed by these enterprises are large in size and expensive. During processing, it is crucial to ensure the accuracy of the processed parts and minimize scrap. Therefore, imported tools are often used in these industries.

- Enterprises Using CNC Machine Tools More Frequently: As the saying goes, "A good horse with a good saddle." In order to improve processing efficiency and product quality, the efficiency of using CNC machine tools should be fully utilized.

- Foreign-funded Enterprises: In these enterprises, more emphasis is usually placed on production efficiency and quality assurance. In addition, there are many other industries, such as the mold industry, military industry enterprises, etc., where the use of CNC tools is also very common.

4.Classification and Characteristics of CNC Tools:

1). According to the tool structure, they can be divided into:

- Integral type: The tool is integrated and made from a single blank without separation.

- Welding type: Connected by welding method, the tool shank.

- Machine clamping type: Machine clamping type can be divided into non-indexable and indexable. CNC tools usually adopt machine clamping type!

- Special types: Such as compound tools, shock-absorbing tools;

2). According to the materials used for the tools, they can be divided into:

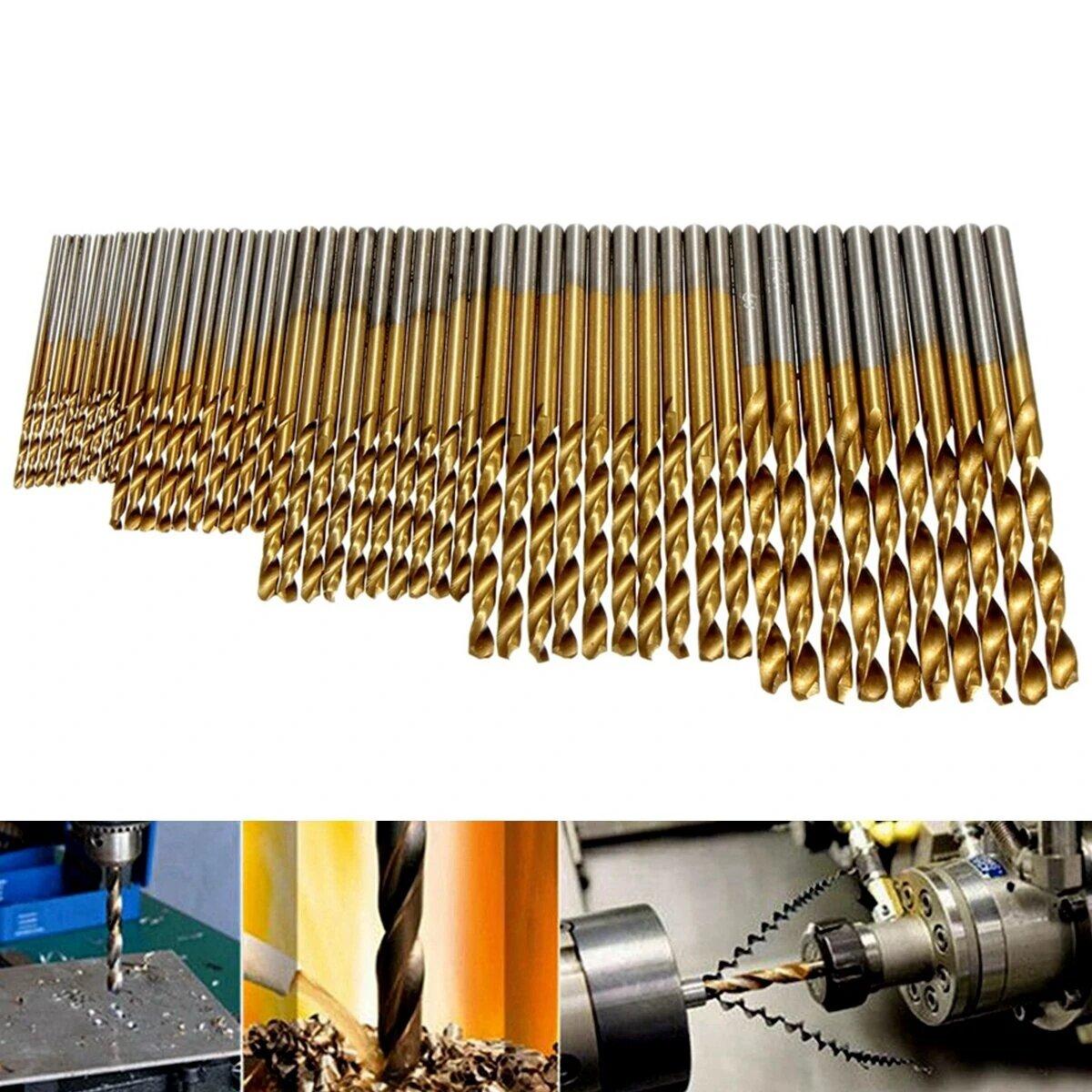

- High-speed steel tools;

- Hard alloy tools;

- Ceramic tools;

- Ultra-high-pressure sintered body tools;

3). According to the processing methods of the tools, they can be divided into:

- Turning tools: including outer circle, inner circle, thread, slotting, and cut-off tools, etc.

- Drilling tools; including drill bits, taps, reamers, etc.

- Boring tools;

- Milling tools: including face milling cutters, end mills, three-edge milling cutters, etc.

Leave a comment