In the dynamic world of machine processing, where precision and efficiency are paramount, the incorporation of innovative technologies is reshaping the landscape. The power head, a critical component in machining operations, has emerged as a game-changer, driving advancements in speed, accuracy, and versatility. This article explores the multifaceted applications of power heads in machine processing and their pivotal role in achieving superior machining outcomes.

1. Introduction to Power Heads:

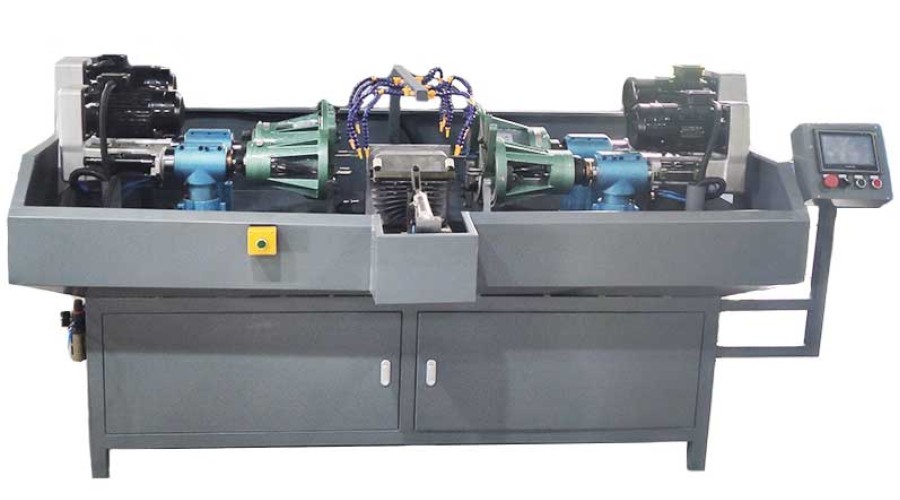

A power head, also known as a milling head or spindle head, is a specialized attachment designed to enhance the capabilities of machine tools, particularly milling machines. It provides additional functionality by enabling various machining operations beyond what a standard machine tool can achieve. The power head is characterized by its ability to rotate, tilt, or perform other dynamic movements, significantly expanding the scope of machining possibilities.

2. Precision Drilling and Tapping:

One of the primary applications of power heads lies in precision drilling and tapping operations. The ability to control the rotational speed, feed rate, and depth of the tool with precision ensures accurate hole placement and consistent thread tapping. This is crucial in industries such as aerospace and automotive manufacturing, where precision-drilled holes are fundamental to the assembly of complex components.

3. Contouring and Milling Operations:

Power heads play a pivotal role in contouring and milling applications, allowing for the creation of intricate shapes and detailed features on workpieces. The dynamic movement capabilities of the power head enable it to approach the workpiece from various angles, facilitating the production of complex components with superior surface finishes. This is particularly valuable in the production of molds, dies, and customized parts.

4. Multi-Axis Machining:

In the era of advanced manufacturing, multi-axis machining has become a cornerstone of precision. Power heads contribute significantly to this by enabling multi-axis movements, such as tilting and swiveling. This versatility allows for simultaneous machining along multiple axes, enhancing efficiency and expanding the range of achievable geometries. Industries such as aerospace and medical manufacturing benefit from the intricate capabilities of power heads in achieving complex part designs.

5. High-Speed Machining:

Power heads are instrumental in high-speed machining applications, where rapid material removal is essential. The ability to achieve high rotational speeds and maintain stability during cutting operations enhances productivity and reduces cycle times. This is particularly advantageous in industries with demands for high-volume production, such as automotive and consumer electronics manufacturing.

6. Precision Grinding:

Beyond traditional milling operations, power heads find applications in precision grinding processes. The controlled rotational movement, combined with precise feed rates, enables the production of components with tight tolerances and superior surface finishes. This is critical in applications where precise dimensional accuracy and surface quality are non-negotiable, such as in the production of medical implants.

7. Automated Machining Systems:

Power heads are integral components in automated machining systems, contributing to the advancement of Industry 4.0. When integrated with robotic systems and CNC controllers, power heads facilitate automated tool changes, dynamic adjustments, and adaptability to varying workpiece geometries. This level of automation enhances overall process efficiency and reduces the need for manual intervention.

8. Prototyping and Small-Batch Production:

In industries requiring rapid prototyping and small-batch production, power heads prove to be invaluable. The dynamic movements and precise control allow for the efficient production of prototypes and customized components, catering to the growing demand for flexibility and quick turnaround times in product development.

Conclusion:

The application of power heads in machine

processing represents a paradigm shift in the capabilities of machining

operations. From precision drilling to multi-axis machining and high-speed

operations, power heads empower manufacturers to achieve levels of accuracy and

efficiency that were once considered unattainable. As technology continues to

evolve, the role of power heads in shaping the future of advanced machine processing

is poised to expand further, driving innovation and excellence in

manufacturing.

Leave a comment