DIP switches are critical components for manual configuration in industrial, consumer, and communication devices. However, improper installation or environmental factors can lead to signal instability, intermittent connectivity, or complete device failure. This guide addresses common DIP switch issues and provides actionable solutions, with a focus on the 10-Way DIP DIL Red PCB Switch as a reliable fix for these challenges.

1. Problem: Intermittent Signals or Poor Contact

Causes:

• Oxidation or dirt buildup on contacts.

• Loose mounting or incorrect pressure applied during installation.

Solutions:

• Use gold-plated contacts: Switches like the 10-Way DIP DIL Red PCB Switch feature gold-plated terminals to resist corrosion and ensure stable connections, even in humid or high-vibration environments.

• Verify alignment and torque: Ensure switches are vertically mounted with 2.54mm pitch alignment. Apply consistent pressure to avoid false contacts.

• Clean oxidized contacts: For legacy switches, use isopropyl alcohol and a soft brush to remove debris.

2. Problem: Incorrect Configuration or Signal Mismatch

Causes:

• Mislabeling of switch positions.

• Accidental toggling during handling.

Solutions:

• Opt for clear labeling: The 10-Way DIP DIL Red PCB Switch includes on/off indicators and a vibrant red body for quick visual identification.

• Implement locking mechanisms: Use switches with tamper-proof covers or retaining clips to prevent accidental adjustments in critical systems.

3. Problem: Physical Damage or Wear

Causes:

• Repeated manual adjustments exceeding switch durability limits.

• Mechanical stress from improper handling.

Solutions:

• Select high-cycle switches: The 10-Way DIP DIL Red PCB Switch supports up to 10,000 cycles, making it ideal for high-frequency use.

• Avoid over-tightening: Use PCB standoffs or mounting hardware that matches the switch’s 2.54mm pitch to prevent stress on terminals.

4. Problem: Environmental Interference

Causes:

• Dust, moisture, or temperature fluctuations affecting performance.

Solutions:

• Prioritize IP-rated designs: While DIP switches are inherently rugged, gold-plated contacts (as in the 10-Way DIP DIL Red PCB Switch) enhance resistance to environmental wear.

• Seal enclosures: Use conformal coating or gaskets to shield switches in harsh settings.

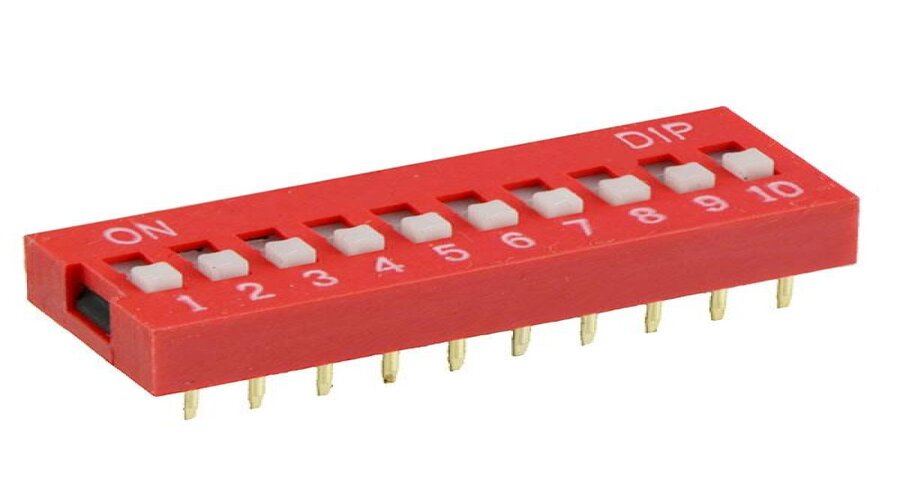

Product Spotlight: 10-Way DIP DIL Red PCB Switch

Engineered for reliability, the 10-Way DIP DIL Red PCB Switch addresses these common issues with:

• SPST contacts: Simplify circuit design with single-pole, single-throw functionality.

• 24VDC/25mA rating: Safely handle low-power applications without overheating.

• Standardized 2.54mm pitch: Ensures compatibility with prototyping boards and legacy systems.

Applications:

• Industrial machinery control panels requiring vibration resistance.

• IoT gateways needing fail-safe manual overrides.

• Legacy device upgrades avoiding costly redesigns.

Preventive Best Practices

1. Conduct pre-installation inspections: Check for contact oxidation or physical defects.

2. Test configurations under load: Validate switch performance at maximum voltage (24VDC) and current (25mA).

3. Document switch positions: Label configurations permanently to avoid setup errors.

DIP switch issues often stem from environmental exposure, installation errors, or component fatigue. By selecting switches with robust designs—like the 10-Way DIP DIL Red PCB Switch—engineers can mitigate these risks while ensuring long-term reliability.

Visit our Website to explore bulk pricing for the 10-Way DIP DIL Red PCB Switch, request datasheets, or consult our team on integrating switches into your next design. Contact us today to transform fragile setups into rugged, signal-stable solutions.

Leave a comment