Spring loaded push button switches are a versatile and essential component in the world of electronics and electrical engineering. Known for their reliability, durability, and ease of use, these switches play a crucial role in controlling various devices and systems. Whether you are a beginner looking to understand the basics or an expert seeking advanced knowledge, this comprehensive guide will provide you with everything you need to know about spring loaded push button switches.

Features of Spring Loaded Push Button Switches

Spring loaded push button switches come in a variety of configurations to suit different applications. One common type is the momentary switch, which is designed to return to its original position when released. This feature makes momentary switches ideal for applications where temporary activation is required, such as in push-to-talk communication systems or safety devices.

Another key feature of spring loaded push button switches is their waterproof construction. This makes them suitable for use in outdoor environments or applications where exposure to moisture is a concern. The waterproofing also enhances the durability of the switches, ensuring long-term performance and reliability.

Furthermore, spring loaded push button switches are often equipped with LED indicators, such as the 2Pcs Yellow Led Momentary Switch mentioned in the title. These LEDs provide visual feedback, indicating the status of the switch and helping users easily identify when it is activated. The incorporation of LEDs adds a modern touch to the switches and enhances their usability in low-light conditions.

Applications of Spring Loaded Push Button Switches

Spring loaded push button switches find applications in a wide range of industries and settings. From automotive and industrial machinery to consumer electronics and medical devices, these switches are used to control various functions and operations. In automotive applications, spring loaded push button switches are commonly used for starting engines, activating lights, or operating windows and doors.

In industrial settings, these switches are employed in control panels, machinery, and equipment to enable operators to easily start or stop processes. The momentary action of the switches allows for precise control, making them suitable for tasks that require quick and accurate responses. Additionally, the waterproof and durable nature of the switches makes them well-suited for use in harsh industrial environments.

Installation and Wiring of Spring Loaded Push Button Switches

Installing a spring loaded push button switch is a straightforward process that can be completed with basic tools and equipment. The switches are designed to fit into a standard 16mm mounting hole, making them compatible with a wide range of panels and enclosures. To install the switch, simply insert it into the mounting hole and secure it in place using the provided locking nut.

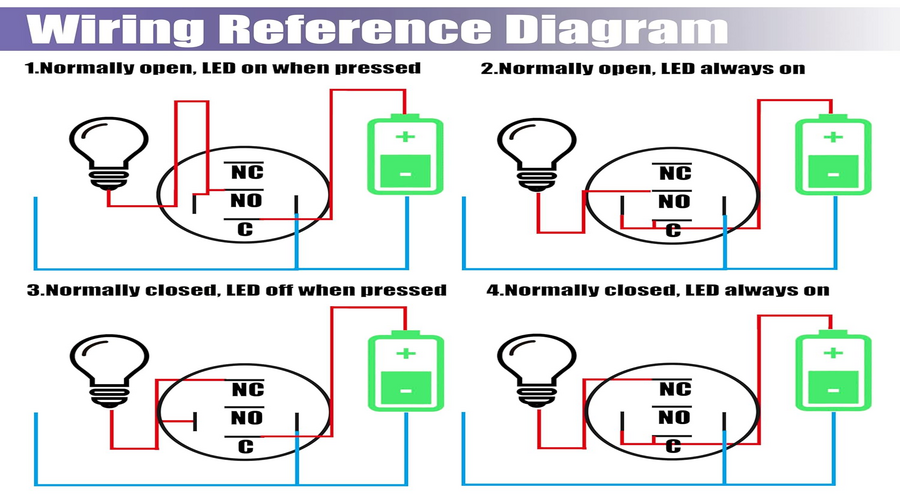

When it comes to wiring the switch, most spring loaded push button switches come with wire connectors that simplify the installation process. These connectors allow you to easily connect the switch to the electrical circuit without the need for soldering or crimping. The wires can be connected to the appropriate terminals on the switch, ensuring proper functionality and reliable operation.

Conclusion

In conclusion, spring loaded push button switches are versatile, reliable, and essential components that are used in a variety of applications. Whether you need a momentary switch for temporary activation, a waterproof switch for outdoor use, or an LED switch for visual feedback, there is a spring loaded push button switch that meets your requirements. Understanding the features, applications, and installation process of these switches will help you make informed decisions when selecting and using them in your projects.

Leave a comment