New

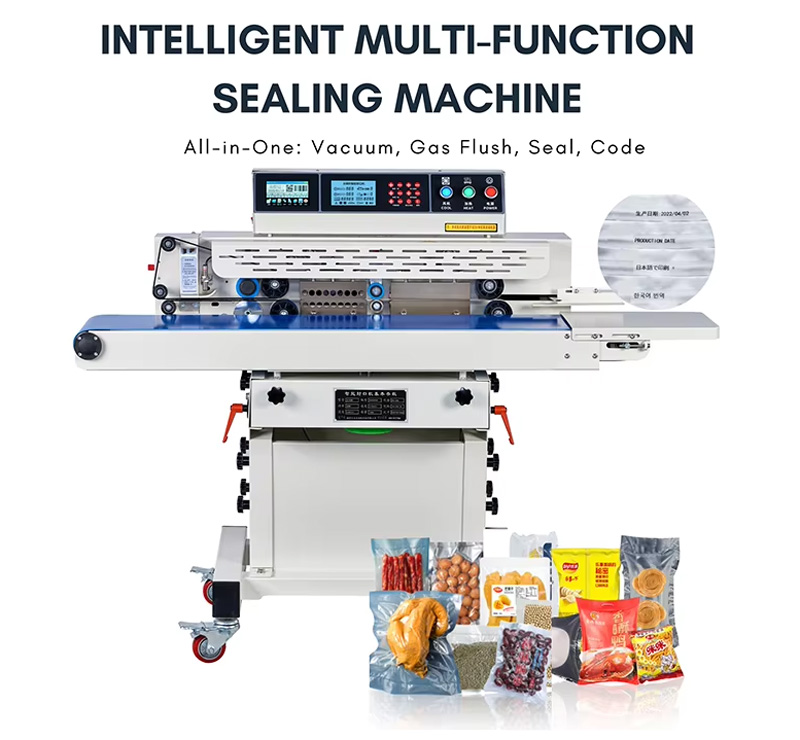

Full Stainless Body Vacuum Sealers, Full Stainless Body Vacuum Packaging and Sealing Machine

from

$2,800.00

Ex Tax: $2,800.00

- Stock: In Stock

- Model: SCJWSM280QP

- Dimensions: 1,500.00mm x 620.00mm x 1,060.00mm

- SKU: SCJWSM280QP

Products Sold: 0

Product Views: 112

Ask a Question About This Product

- Description

Model: SCJWSM280QP

Voltage: 220V/50Hz

Type: Horizontal Continuous Band Vacuum Sealers

Motor Power: 1000W

Function: Gas Flush, Vacuum, Seal, Date Print, Count

Temperature Control Range: 0-280℃

Seal Width: 10mm(Customizable)

Conveying motor: 24V/120W/18K

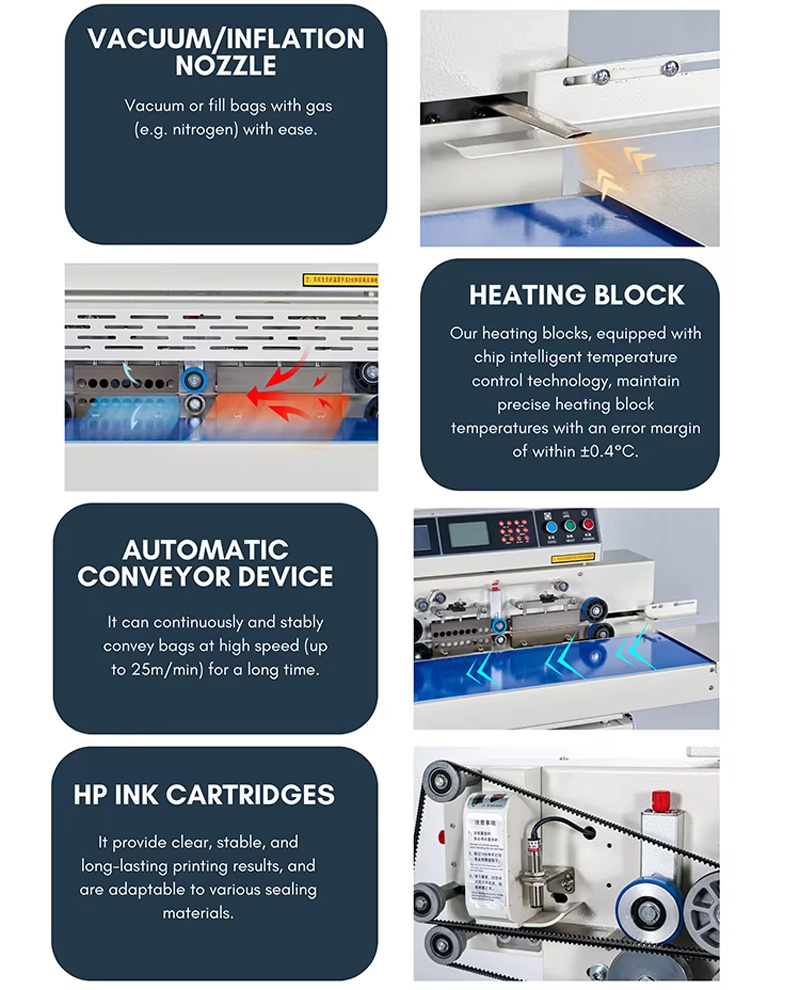

Seal Speed: 0-25m/mins

Pumping vacuum: -0.05-0.088Mpa

Maximum bag size: 400*300*0.15mm

Air consumption: 280L/min

Conveyor Load: 10KG

Mahcine Weight: 110KG

Machine Size: 1500*620*1060mm

Machine Body Materical: Carton steel

Inkjet Print Width: Max.12.7mm

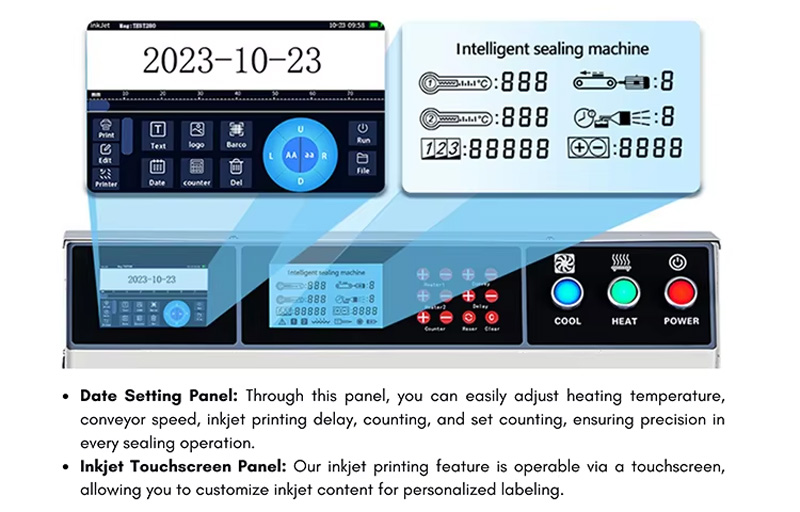

Screen Language Settings: English, Chinese, etc

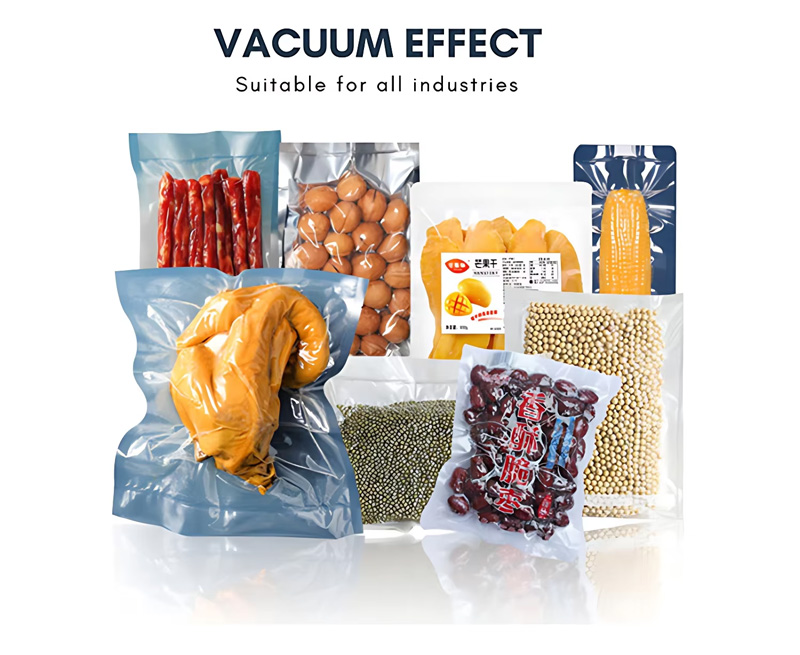

Seal/Vacuum/Gas Fill: This machine is appropriate for heat-sealing plastic bags that require sealing.

Other Customization Options

Stainless steel body、Roller printing、Ribbon coding、Seal widening、Bag margin lengthening

The main differences and advantages between our machine and ordinary sealing machines on the market are as follows:

1. Reasonable machine structure design ensures that it is significantly superior to ordinary sealing machines on the market in terms of stability and durability

2. The intelligent control system can accurately control the temperature within a deviation of plus or minus 0.4 degrees Celsius, and can detect and calibrate the working condition of the whole machine in real time.

3. The inkjet coding system uses industrial grade motherboards to solve many industry problems and pain points such as static electricity, interference, stability, no damage to ink cartridges, and clear printing.

4. Material technology: We all use high-quality accessories and materials.

- Reviews