- Stock: In Stock

- Model: SCJ009486

- SKU: SCJ009486

Available Options

Ask a Question About This Product

- Description

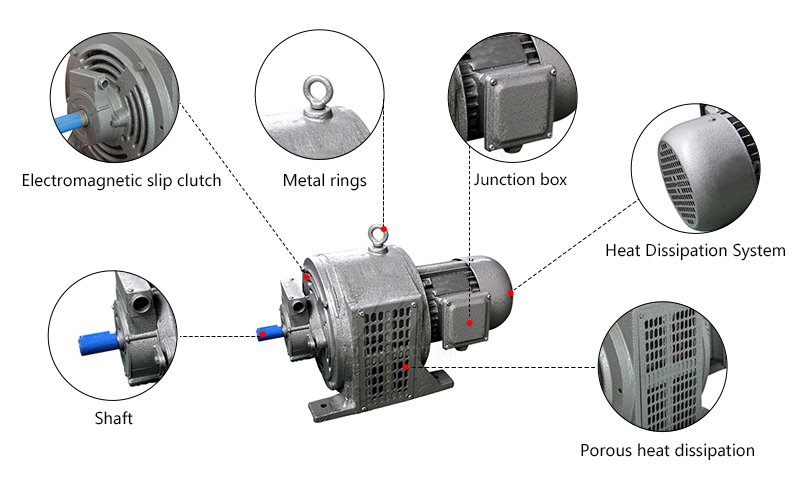

3-Phase Asynchronous Motor with Clutch 15hp (11kW)

Brief

Description

15hp/11kW synchronous motor with clutch at affordable price, running at 380V 50Hz, IP grade IP21, the altitude is less than 1000m and ambienttemperature is -15℃-+40℃.

15hp (11kW) 3 Phase Asynchronous Motor with Clutch Specification

| Model | SCJ009486 |

| Capacity | 11kW |

| Rated Torque | 69.1Nm |

| Speed adjustable Range | 1250-125r/min |

| Speed Changing Rate | 3% |

| Rated Voltage | 380V |

| Installation | B3 |

| Frequency | 50Hz |

| Phase | 3 phase |

| Certification | CE, CCC, IS9001, IS2008 |

| IP Grade | IP21 |

| Efficiency | IE1/IE2/IE3 |

| Frame | Cast Iron or aluminum |

| Weight | 420kg |

| Ambient temperature | -15℃~40℃ |

| Altitude | not exceeding 1000 Meters |

| Duty | Continuous running |

| Insulation Grade | B |

| Warranty | 1 year |

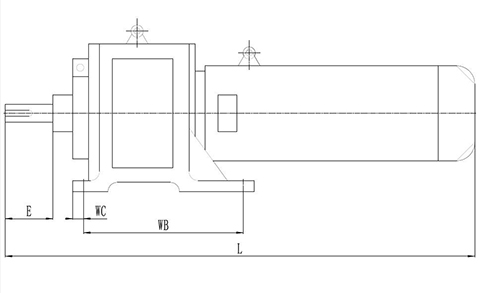

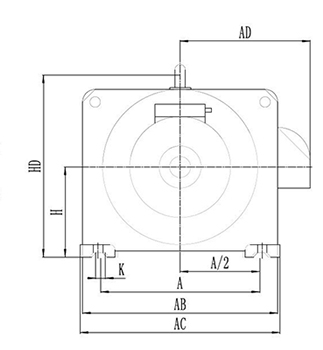

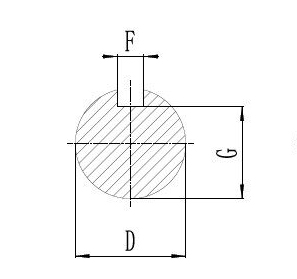

15hp (11kW) 3 Phase Asynchronous Motor with Clutch Dimensions

Details

Tips: How to Check and Maintain the 15hp (11kW) 3-Phase Asynchronous Motor with Clutch?

A. The motor cannot rotate after power is applied, but there is no strange sound, no smell and smoke.

1. Cause of failure

① power is not on (at least two phases are not on).

②Fuse fused (at least two phases fused).

③ overcurrent relay is set too small.

④ control equipment wiring errors.

2. Troubleshooting

① check the power circuit switch, fuse, junction box at whether there are broken points, repair.

② Check the fuse type, the reason for fusing, and change the new fuse.

③Adjust the relay adjustment value to match the motor.

④ Correct the wiring.

B. The motor no-load current is not balanced, the three-phase phase difference is large

1、Cause of failure

①When rewinding, the number of turns of stator three-phase winding is not equal.

② Wrong winding head and tail end connection.

(iii) unbalanced power supply voltage.

④There is a short circuit between turns of the winding, coil reversal and other faults.

2. Troubleshooting

① re-wind the sub-winding.

②Check and correct.

③ Measure the power supply voltage and try to eliminate the imbalance.

④Clear the winding fault.

- Reviews