Nema 23 Stepper motor, 1A, 1.8 degree, 2 phase 6 wires

from

$63.31

Ex Tax: $63.31

- Stock: In Stock

- Model: SCJ009412

- SKU: SCJ009412

Products Sold: 0

Product Views: 1312

Available Options

Ask a Question About This Product

- Description

Nema 23 Stepper motor, 1A, 1.8 degree, 2 phase 6 wires

Brief

Favorable price Nema 23 stepper motor, 0.9Nm holding torque, 1.8 deg. step angle.

Description

Nema 23 Stepper motor, 1A, 2 phase 6 leads, 1.8 degree.

Specification

| Electrical Specification | Model | SOCOJE57STH56-1006 |

| Matched Driver Model | SCJ009412(Click it to see more info) | |

| Step Angle | 1.8° | |

| Holding Torque | 0.9Nm | |

| Rated Current/phase | 1A | |

| Phase Resistance | 7.4Ω | |

| Inductance | 10mH | |

| Rotor Inertia | 280g-cm2 | |

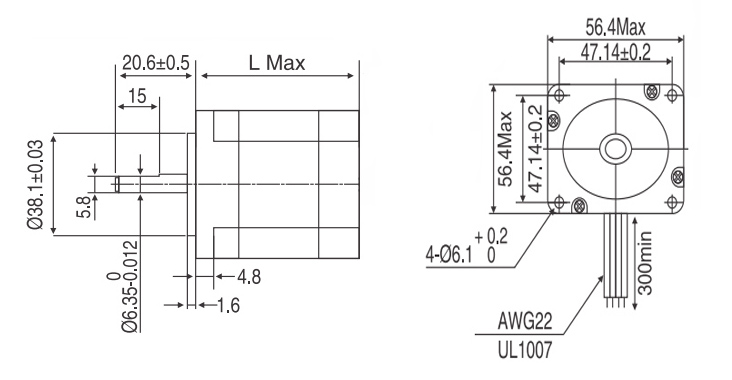

| Physical Specification | Frame Size | 57 x 57mm |

| Length | 56mm | |

| Shaft Diameter | Φ6.35mm | |

| Shaft Length | 19mm | |

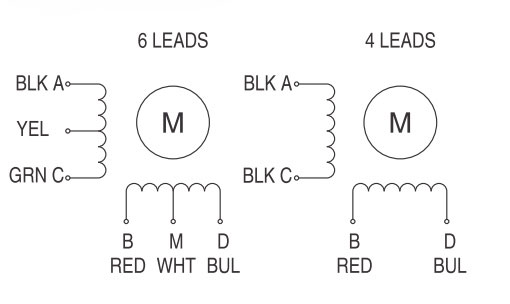

| Motor Leads | 6 | |

| Weight | 0.68kg | |

| Technical Parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max. (rated current, 2 phase on) | |

| Ambient Temperature | -20℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 500V AC for one minute | |

| Shaft Radial Play | 0.02Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g | |

| Quality Assurance | Warranty Period | 12 months |

| Certificate | CE, ROHs, ISO/SGS9001 |

Dimensions: (Unit=mm)

L Max=56mm

L Max=56mm

Wiring Diagram

Tips: Reasons for out of step of stepper motor

- The working torque of the stepper motor is not enough and there is not enough ability to drive load.

- The acceleration and deceleration process for starting and stopping of stepper motor is not sufficient. The stepper motor runs out of steps during acceleration and deceleration process.

- Power of the stepper motor is not enough, thus the input power of stepper motor is not enough, leading to out of step of the motor.

- Drive voltage of the stepper motor is not enough or the drive current is too low.

- Driver or controller receives the signal interference.

- Load capacity of motor is reduced due to the system resonance of the stepper motor, thus the step out of the motor is caused.

- Stepper motor driver is not matched with the signal of controller.

- The gap or the back-and-forth clearance error of synchronizing gear or reducer is not compensated through programming or the compensation value is not correct.

- There is something wrong with the control programming.

- Reviews