High Precision Standard And Custom Stainless Steel Single and Double Universal Joint Shaft Coupling 200Pcs

from

$11.50

Ex Tax: $11.50

- Stock: In Stock

- Model: SCJ007555

- SKU: SCJ007555

Products Sold: 0

Product Views: 783

Ask a Question About This Product

- Specifications

| Industry-specific attributes | |

| CNC Machining or Not | Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

| Other attributes | |

| Micro Machining or Not | Micro Machining |

| Place of Origin | Guangdong, China |

| Logo | Accept Custom Logo |

| File Format | STL. STEP. STP. PDF |

| OEM/ODM | OEM ODM CNC Milling Turning Machining Service |

| Sample | Within 7 Days |

| Model Number | BO-478 |

| Product name: | Universal Joint Shaft Coupling |

| Process | Cnc Machining + Surface Treatment |

| Type | DRILLING, Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| PACKAGE | Plastic Bag + Box + Carton |

| Delivery time | 35 Days |

| Material | stainless steel, aluminum, brass ect |

| Certificate: | ISO9001,ISO13845,ISO9100 ,IATF16949 |

| Packaging and delivery | |

| Packaging Details | Packaging Detail:bubble pack individually to prevent from damaging and scratches in transporting, then in carton |

| Supply Ability | |

| Supply Ability | 100000 Piece/Pieces per Day |

- Description

Products Description

Product Item | Dongguan Nut And Bolt Manufacturer Customized Hex Nuts Rivet Wheel Nuts For Car | ||||||

Materials | Aluminum 6061-T6 | ||||||

Production Capacity | 5000 pieces per month | ||||||

Our service | SWISS lathe turning; 3,4,5 Axis CNC milling; Grinding, Polishing, Plating, Anodize | ||||||

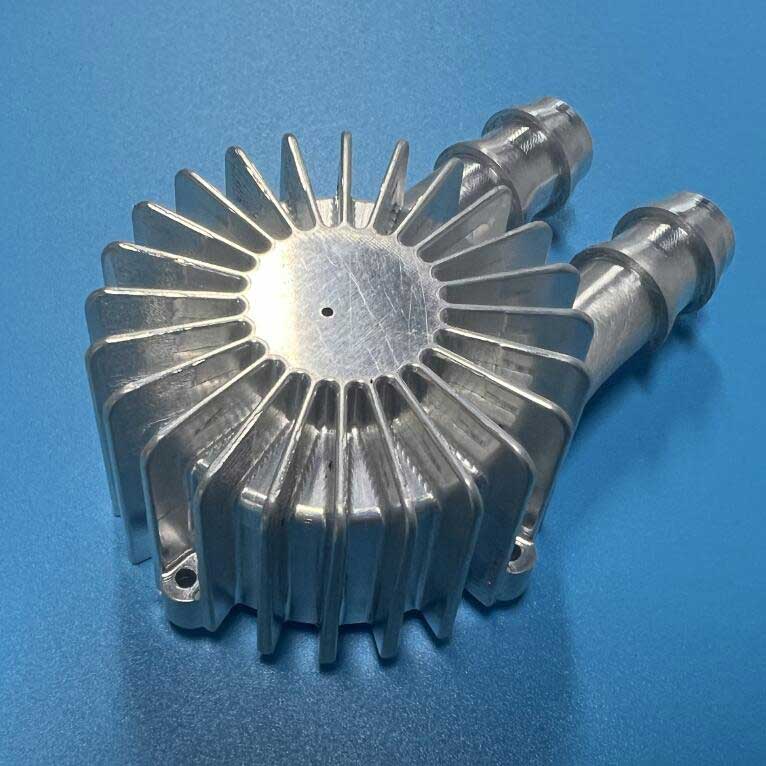

Application | Air Conditioner | ||||||

What we can produce is

Application

The impeller is the rotary part of the body – the compressor wheel driving the medium, i.e. the air or steam. It is used for large volumes of a medium, e.g. in turbo compressors.

We place high demands on the material, manufacturing method and stress on the material during the actual manufacturing process.

For this purpose, we utilize our high-tech devices that we are continually innovating.

For this purpose, we utilize our high-tech devices that we are continually innovating.

- Reviews