- Stock: In Stock

- Model: SCJ009528

- SKU: SCJ009528

Available Options

Feature

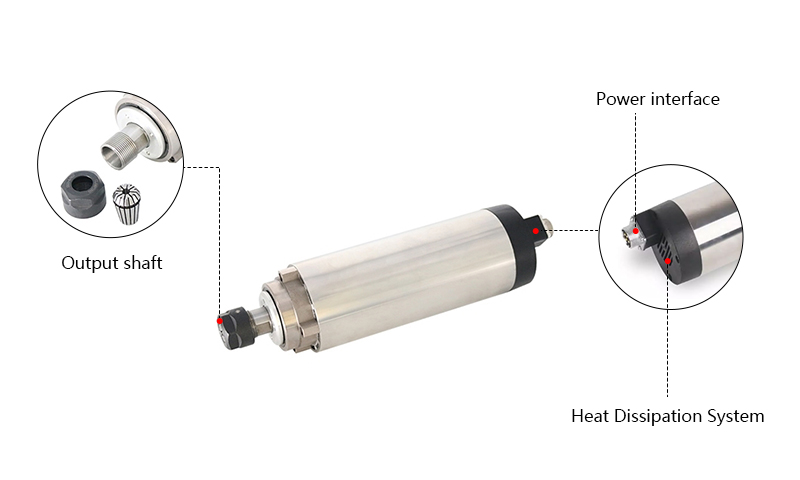

- Spindle motor with air cooling fan and ER20 collet ensures smooth running.

- Fast response, strong overload capacity, low noise and high mechanical precision.

- High quality 4 pcs bearings (7005Cx2 + 7002Cx2), runout off less than 0.01mm, tapered bore less than 0.005mm.

- P4 grade ceramic ball bearings used as spindle bearing, which improves the service life under high speed revolution.

- Lubricated with grease, which is resistant to 200 degrees high temperature.

- Tight sealing and two-layer dustproof design.

Ask a Question About This Product

- Technical Parameters

Specification

| Model | STF80-2.2-ER20 |

| Matched VFD Model | GK3000-2S0037 (5 hp single to three phase VFD) GK3000-4T0037G (5 hp three phase VFD) |

| Power | 2.2 kW |

| Phase | 3 phase |

| Speed | 24000 rpm |

| Voltage | 3-phase 220V±10% AC |

| Current | 8.0A |

| Frequency | 400Hz |

| Torque | 0.85 Nm |

| Number of Pole | 2 poles |

| Cooling Type | Air-cooled |

| Installation Method | Horizontally or Vertically (When the motor is installed, the radial runout standard is required to be within 5um, and the chuck is generally 10um-15um.) |

| Lubrication | Grease |

| Thermal Class | Class F |

| Protection Class | IP50 |

| Certification | CE |

| Warranty | Bearings for half a year, other parts for one year |

| Joint of Nose | ER20 (φ3.175 mm - φ13 mm) |

| Bearings Type | 7005C P4*2 & 7002C P4*2 |

| Application | Woodworking & Plastic |

| Weight | 4.8 kg |

| 2.2kW Air Cooled Spindle Motor CAD Drawings |

- Description

2.2 kW CNC spindle motor for sale at competitive price, 24000 rpm speed, 0.85 Nm torque, 400Hz frequency, 3 phase 380V AC operating voltage, ER20 (φ3.175 mm - φ13 mm) collet.

Application:

This series air-cooled electric spindle motors mainly match with variable frequency drives or engraving machines, CNC router machine, and used for high speed profiling, drilling, cutting, engraving and groove milling of wood, metal, plastics, foam, rubber and other materials.

Note: The spindle motor and VFD shall be suitable with each other. The specifications and parameter settings of the VFD shall match the nominal parameters of the spindle motor. Otherwise, it will burn the spindle motor if the settings are not correct.

Details:

Tips: Servo Motor vs. Spindle Motor in CNC Machine

The main requirements of CNC machine tools for servo motors are:

- Mechanical characteristics: The speed drop and rigidity of the servo motor are required to be small.

- Requirements for rapid response: This is more stringent in contour processing, especially for high-speed processing of objects with large curvatures.

- Speed adjustment range: This can make CNC machine tools suitable for various cutting tools and processing materials, suitable for various processing techniques.

- There is a certain output torque and a certain overload torque is required. The nature of the mechanical load of the machine tool feed is mainly to overcome the friction of the table and the resistance of cutting, so it is mainly the nature of "constant torque".

The main requirements for high-speed electric spindles motor are:

- Sufficient output power. The spindle load nature of CNC machine tools is similar to "constant power". That is, when the spindle motor speed of the machine tool is high, the output torque is small; when the spindle speed is low, the output torque is large. That is, the requirement of the spindle drive device must have the nature of "constant power".

- Speed adjustment range: In order to ensure that the CNC machine tool is suitable for various cutting tools and processing materials; it is suitable for various processing techniques, and the spindle motor is required to have a certain speed adjustment range. But the requirement for the spindle is lower than the feed.

- Speed accuracy: Generally, the static difference is required to be less than 5%, and the higher requirement is less than 1%.

- Fast: The spindle drive device is sometimes used for positioning function, which requires it to also have a certain speed.

- Reviews